EQUIP YOUR ENGINEERS WITH THE POWER OF MACHINE LEARNING

Made with steel sector and needs in mind

Run quick (<1 min) evaluations before training full fledged models

Train models with years of data in minutes on an 8-core CPU

Apply to any numerical/classification problem. Train based on customized metrics (R2, MSE, etc)

Use trained models for on-line prediction within QMOS suite

Create, store and schedule a large array of models

Predictive Analytics

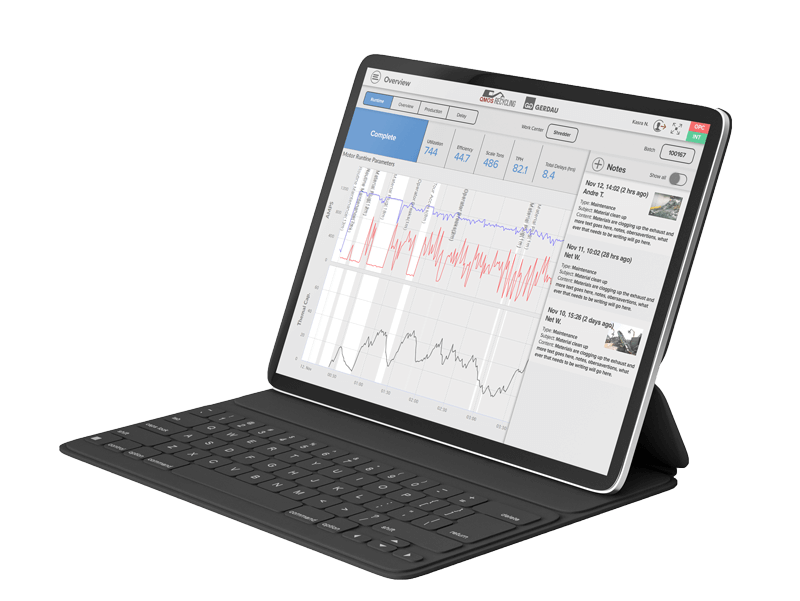

Use our brand new software suite to create and train models that provide high accuracy, high explainability and high interpretability.Analyze key relationships between your process, production and quality parameters using our out of the box visualization toolkit. Schedule training tasks to be completed at regular intervals to keep models up to date.

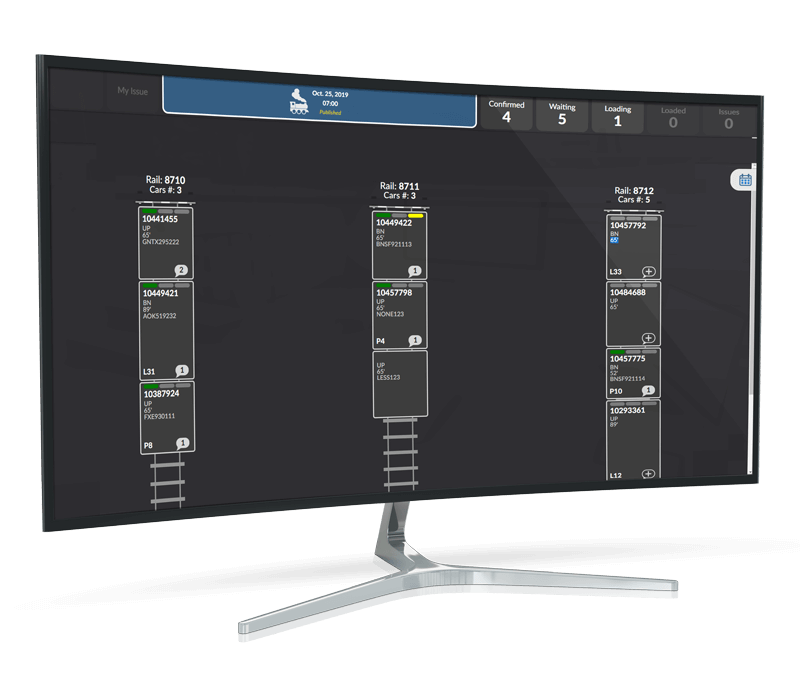

Utilize our product/location matching algorithm to streamline your product warehouse. Reduce forklift/crane travel time and get material out of the plant and onto the road faster. Our approach can generate simple best practice instructions all the way to detailed location management based on a daily production schedule.

In addition to running predictive analytics on your local network, you can harness the processing power of Google Compute Engine. Dramatically reduce training time and access your models anywhere with an internet connection. Feel at ease with the latest authentication and authorization protocols in place. Your model data will be securely encrypted and stored on Google Cloud.

Integrate your best models in QMOS workflow for real-time prediction. View accurate physicals predictions for each chemistry sample directly in QMOS screens and disposition your heats accordingly. Set up automatic retraining of models to guarantee ongoing accuracy.

Reduce the melt shop scrap and alloy usage through our comprehensive optimization models. Create templates and analyze the outputs by adjusting scrap/alloy chemical and physical requirements, physical process conditions, material cost and availability.